By Mariola Sánchez-González and David Pérez-Terrazas

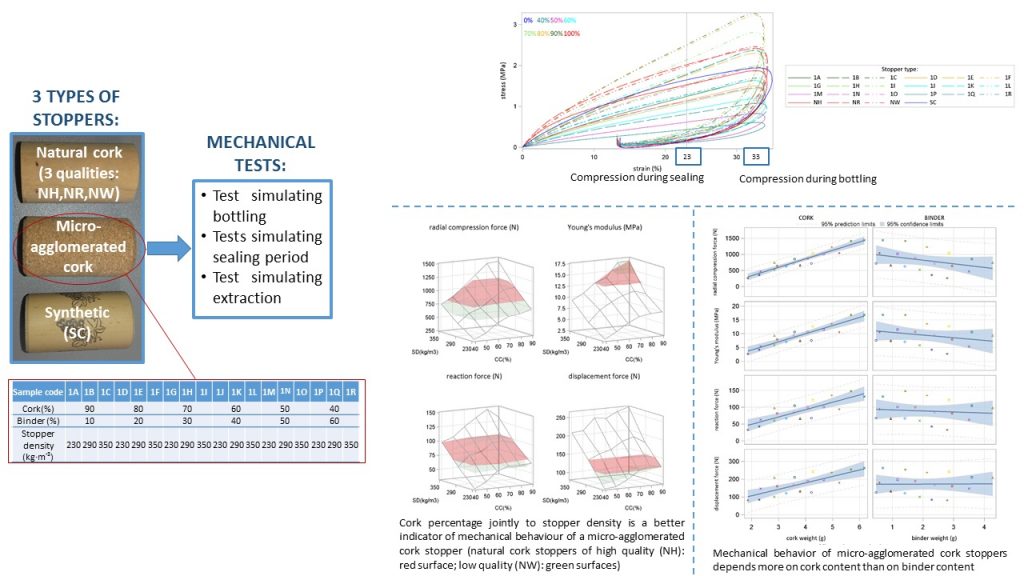

Most bottles of wine consumed in the world are sealed with cylindrical stoppers which can be classified into three types: natural cork stoppers, made from a single piece of natural cork; cork-based stoppers (also known as technical cork stoppers) obtained from agglomerated or micro-agglomerated cork and comprising one or several pieces; and synthetic stoppers, which can be molded by injection or extrusion. In cork-based stoppers cork is mixed with other materials, mainly binder, so it would be interesting to determine the minimum cork content required to achieve a cork-like behaviour. In this study we compared natural cork stoppers, micro-agglomerated cork stoppers and co-extruded synthetic closures through different tests which simulate the bottling process, the beginning of the sealing period and the extraction process (Sánchez-González and Perez-Terrazas, 2018a; Sánchez-González and Pérez-Terrazas, 2018b). We tested micro-agglomerated cork stoppers with different percentages of cork tin their formulation allowing us to determine the percentage of cork that should be present in a cork-based stopper to achieve a cork-like behavior from a mechanical perspective.

The micro-agglomerated cork stoppers tested in this study are composed of cork granulate and binder alone, with no other auxiliary products so that the effect of cork percentage on the mechanical behaviour of the stoppers can be assessed correctly. As regards the percentage of cork which should be present in a cork-based stopper, our results suggest that to clarify this question, the stopper density should be taken into account. Accordingly, cork percentage together with stopper density, provide a better indicator of the mechanical behaviour of a micro-agglomerated cork stopper. Furthermore, the binder content is not as decisive as cork content with regard to the mechanical behavior of micro-agglomerated cork stoppers. These results highlight the versatility of cork-based stoppers from a mechanical perspective. It is possible to design micro-agglomerated cork stoppers with certain formulations capable of improving, equalling or diminishing the mechanical characteristics of natural cork stoppers.

However, if our results are to be extrapolated to other cork-based stoppers, the specific characteristics of the stoppers tested in our study should be taken into account, as should the characteristics of the mechanical tests. The size of the cork particles and the presence of micro-spheres or other additives in the composition of stoppers are variables that could affect their mechanical behaviour (Motte et al., 2017). The duration of the sealing period is another influential factor. In this study we tested the evolution of the relaxation force over the first 24h after corking, although it would be of interest to extend this period. Another important factor to consider is hydration (Lagorce-Tachon et al., 2015, 2016), in this study all stoppers were tested previous acclimatization at 20°C and 65% of relative humidity, however is important to point out that mechanical properties of wine stoppers can change under different relative humidity environments. Hence, further research is needed in order to provide a specific answer to the question posed with regard to mechanical behaviour.

In addition, other aspects such as sensorial and chemical factors must also be considered. A suitable closure for wine should scarcely interact with the wine and should correctly regulate the gaseous exchange with the external atmosphere, which insures excellent conservation and gradual evolution of the wine in the bottle (Karbowiak et al., 2010; Lopes et al., 2012). The stopper must also be sufficiently elastic to guarantee the maintenance of liquid tightness for prolonged periods of time, while at the same time facilitating easy extraction from the bottle by the consumer (Chatonnet and Labadie, 2003). Therefore, the comparative performance of the different types of stoppers can be assessed from chemical, sensorial, mechanical and physical perspectives. However, there are other considerations that must be taken into account when choosing a stopper, namely, ecological, environmental and socioeconomic aspects. Cork is considered among the most important forest products and the associated economic activities form part of the Bioeconomy. Cork is a natural, renewable and sustainable raw material with low environmental impact and which possesses unique properties that make it ideal for the bottling of wine (Pereira, 2007). The use of cork contributes to the conservation of cork oak (Quercus suber L.) woodlands, a Mediterranean ecosystem with high biodiversity which acts as a carbon sink and also fulfils a fundamental ecological function of protection against advancing desertification and erosion. Furthermore, cork oaks contribute significantly to rural development in the areas where they are found.

Those interested in a longer length report can download the working paper at:

https://www.sciencedirect.com/science/article/pii/S2352340918314446

Mariola Sánchez-González, PhD, is researcher at the Forest Research Centre (CIFOR) of the Spanish National Institute for Agricultural and Food Research and Technology (INIA) and is the head of the INIA-CIFOR Cork Laboratory. Her research is focused in generating scientific and technological information for the integrated management of cork value chain from the forest to the industry. She is co-author of more than 40 papers in international scientific journals. She engages in the application of science to real world problems by collaborating with non-academic partners. Besides, she participates as an expert in the Spanish Standards Technical Committee about cork (CTN56) and in the International Organization for Standardization Technical Committee about cork (ISO/TC87).

David Pérez-Terrazas is PhD candidate in Doctorate in Engineering and Management of the Natural Environment at Polytechnic University of Madrid, funded by the Spanish Ministry of Education and Vocational Training (FPU Grant reference FPU17/03295). Doctorate research project focused on characterization of cork granulate for the manufacture of cork-based stopper.

References:

- Chatonnet, P., Labadie, D., 2003. Contrôle de la conformité des bouchons: objectifs et paramètres à l’usage des professionnels. (Conformity assessment of stoppers: objectives and parameters for professional use). Revue Française D’Œnologie 198, 20-29.

- Karbowiak, T., Gougeon, R.D., Alinc, J.-B., Brachais, L., Debeaufort, F., Voilley, A., Chassagne, D., 2010. Wine Oxidation and the Role of Cork. Crit. Rev. Food Sci. Nutr. 50, 20-52.

- Lagorce-Tachon, A., Karbowiak, T., Champion, D., Gougeon, R.D., Bellat, J.P., 2015. Mechanical properties of cork: Effect of hydration. Mater. Des. 82, 148-154.

- Lagorce-Tachon, A., Karbowiak, T., Champion, D., Gougeon, R.D., Bellat, J.P., 2016. How does hydration affect the mechanical properties of wine stoppers? Journal of Materials Science 51, 4227–4237.

- Lopes, P., Roseira, I., Cabral, M., Saucier, C., Darriet, P., Teissedre, P.-L., Dubourdieu, D., 2012. Impact of different closures on intrinsic sensory wine quality and consumer preferences. Wine & Viticulture Journal 27, 34-41.

- Motte, J.-C., Delenne, J.-Y., Barron, C., Dubreucq, É., Mayer-Laigle, C., 2017. Elastic properties of packing of granulated cork: Effect of particle size. Industrial Crops and Products 99, 126-134.

- Pereira, H., 2007. Cork: Biology, Production and Uses. Elsevier, Amsterdan.

- Sánchez-González, M., Perez-Terrazas, D., 2018a. Assessing the percentage of cork that a stopper should have from a mechanical perspective. Food Packaging and Shelf Life 18, 212-220.

- Sánchez-González, M., Pérez-Terrazas, D., 2018b. Dataset of mechanical properties from different types of wine stopper: micro-agglomerated cork, natural cork and synthetic closures. Data in brief 21, 2103-2109.